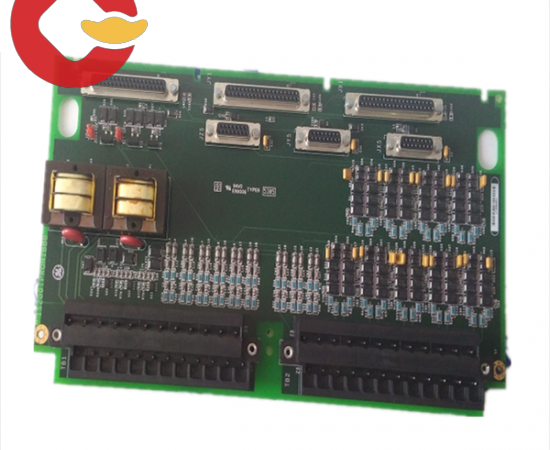

Industrial Power Supply Modules: Types, Features, and a Practical Selection Guide

Industrial power supply modules keep factory equipment running smoothly by delivering stable, usable power. When specified well, they typically reduce downtime, lower heat, and extend component life. From my experience, choosing the right unit comes down to matching the module type and ratings to your environment, loads, and future growth plans.

What these modules do

They convert incoming power into the voltage and current your machines require, buffer against disturbances, and, in some cases, provide continuity during outages. The right choice often balances efficiency, reliability, and maintainability rather than chasing a single spec.

Types of Industrial Power Supply Modules

- Linear Power Supplies: Low noise and simple design; ideal for sensitive analog loads. Trade-off: typically lower efficiency and more heat.

- Switching Power Supplies: High efficiency and compact; suitable for higher power levels and AC-to-DC conversion. Care with EMI filtering is often required.

- Uninterruptible Power Supplies (UPS): Provide backup power and surge protection; crucial where outages or brownouts appear likely.

- Programmable Power Supplies: Precise, adjustable output; helpful for test benches and controlled processes.

- DC-DC Converters: Convert one DC level to another; common in battery-backed or distributed DC systems.

- Redundant Power Supplies: Multi-source architecture for continuous operation if one unit fails; typical in critical lines.

- Modular Power Supplies: Flexible configuration for scalability and redundancy without major redesign.

Key Features That Typically Matter

- Efficiency: Higher efficiency reduces heat and operating costs; look at figures at both 50% and full load.

- Reliability: Overvoltage/overcurrent/overtemperature protections and a solid MTBF figure suggest stable performance.

- Form Factor: DIN-rail, enclosed, or open-frame—match to your panel space and cooling approach.

- Input Voltage Range: Wide-range inputs tolerate grid fluctuations and regional differences.

- Output Ratings: Voltage accuracy, current capacity, and ripple/noise must align with the load’s tolerance.

- Environmental Rating: Operating temperature, derating curve, humidity, vibration, and ingress protection for harsh areas.

- Compliance and Certifications: Safety and EMC approvals help avoid surprises during installation and audits.

Selection Guide: How to Choose for Your Factory

1) Assess the load

List continuous power, peak inrush, and transient demands. In most cases, adding 20–30% headroom helps with thermal margin and future changes.

2) Match the environment

Check ambient temperatures, enclosure airflow, dust or moisture exposure, and vibration. It appears that many failures trace back to insufficient cooling or underestimated derating.

3) Confirm electrical compatibility

- Input: single/three-phase, nominal VAC, frequency, and ride-through capability.

- Output: voltage setpoint, current limit mode, ripple/noise, and hold-up time.

- EMC: noise immunity and conducted/radiated emissions within your plant’s limits.

4) Decide on redundancy and scalability

For critical cells, consider N+1 or parallel operation with proper OR-ing. Modular designs typically simplify expansion without major rewiring.

5) Balance budget and lifetime cost

Higher-efficiency units may cost more upfront but can pay back through lower energy use and reduced cooling. From my experience, fanless designs often cut maintenance in dusty areas.

6) Check compliance and documentation

Verify safety and EMC certificates, installation manuals, and wiring diagrams. Clear documentation speeds commissioning and audits.

7) Evaluate support and warranty

Strong technical support, reasonable lead times, and a dependable warranty reduce risk over the system’s life.

Common Pitfalls to Avoid

- Sizing to average load and forgetting motor or solenoid inrush.

- Ignoring derating above 40–50°C or in sealed panels.

- Overlooking ripple/noise limits on sensitive sensors and PLC inputs.

- Mixing grounds poorly, leading to measurement errors or nuisance trips.

- Skipping surge protection where grid quality is inconsistent.

Quick Specification Checklist

- Input: VAC range, phase, frequency, surge immunity.

- Output: V, A, power rating, regulation, ripple/noise.

- Efficiency at 50% and 100% load; power factor.

- Protections: OVP, OCP/CC, SCP, OTP.

- Hold-up time and ride-through capability.

- Thermals: operating range, derating curve, cooling method (fan/fanless).

- Mechanical: form factor (DIN-rail/enclosed/open-frame), dimensions, connectors.

- Environment: humidity, altitude, vibration, IP rating.

- EMC and safety certifications relevant to your region.

- Control/monitoring: trim range, remote on/off, analog or digital interfaces (e.g., RS‑485/CAN, if needed).

- MTBF/L10, warranty, service and spare availability.

Deployment and Maintenance Tips

- Allow clearance for airflow and follow recommended cable gauges and torque.

- Use proper fusing and breakers on both input and output where applicable.

- Document setpoints and wiring; label outputs to speed troubleshooting.

- Schedule dust cleaning and connector checks; fans, if present, typically need periodic inspection.

- Log operating temperature and load over time to catch early degradation.

Selecting an industrial power supply module is rarely about a single headline spec. With a clear view of loads, environment, and long-term maintenance, most teams can land on a dependable, efficient choice that fits both current needs and future plans.

Leave a comment

Your email address will not be published. Required fields are marked *